The basics of grinding circuit optimisation

This paper provides a simple guiding framework for grinding circuit optimisation, focussing on common themes in past optimisation success stories, the conditions for success and

Read More

The effects of ball filling and ball diameter on kinetic breakage ...

2012.9.1 The ball diameter and charge are important factors for grinding. I have found different than other researchers in terms of some kinetic parameters. I found

Read More

Intelligent Optimal-Setting Control for Grinding Circuits of Mineral ...

2009.4.24 Abstract: During the operation of a grinding circuit (GC) in mineral processing plant the main purpose of control and optimal operation is to control the

Read More

Kinetics of dry grinding of industrial minerals: calcite and barite

2002.11.1 This paper is a detailed analysis of the grinding kinetics of calcite and barite minerals in terms of the specific rates of breakage, the primary breakage

Read More

Comparison of Particle Shapes of Conventionally Ground Barite

2021.2.26 Shape of particles made by grinding is one of the important measures for determining the utilizations of industrial minerals namely barite, calcite, and talc particles,

Read More

Increasing Grinding Circuit Robustness with Advanced Process

INTRODUCTION. Lower ore head grades increase the challenge of mines to maintain or improve the production targets of concentrates. The increased robustness requirements

Read More

(PDF) Optimization and performance of grinding circuits: the case

2020.1.16 Within the scope of the evaluation and optimization of a grinding circuit, the breakage and mineral liberation characteristics of three low grade sulphide gold ore

Read More

The basics of grinding circuit optimisation - AusIMM

This paper provides a simple guiding framework for grinding circuit optimisation, focussing on common themes in past optimisation success stories, the conditions for success and

Read More

COMPARISON OF PARTICLE SHAPES OF CONVENTIONALLY

Shape of particles made by grinding is one of the important measures for determining the utilizations of industrial minerals namely barite, calcite, and talc particles, particularly at

Read More

Ball Mill Grinding Circuit Based on MPC and EID - IEEE Xplore

In this paper, MPC-EID hybrid control is used to control the grinding circuit. Simulation results demonstrate that while controlling the ball mill grinding circuit, the MPC

Read More

Halliburton Barite Grinding Plant Construction

This barite grinding plant, the largest in North America, covers 66,000 square feet including the mill building, maintenance area, bag packing room and warehouse. It has two Williams mills capable of grinding barite in

Read More

Closed Circuit Grinding VS Open Circuit Grinding

2016.10.12 The simplest grinding circuit consists of a ball or rod mill in closed circuit with a classifier; the flow sheet is shown in Fig. 25 and the actual layout in Fig. 9. This single-stage circuit is chiefly employed for

Read More

Grinding Classification Equipment - JXSC Machinery

JXSC grinding classification equipment is the key equipment for crushing materials after they are crushed. The ball mill can process various grinding minerals, non-ferrous metal beneficiation, and new building materials. It

Read More

Silver Barite Treatment Method - 911 Metallurgist

2021.1.12 Recovery of barite at specification grade (plus 92 percent barite) averaged about 60 percent. Use of American Cyanamid AERO Promotor 825, an anionic petroleum sulfonate, and sodium silicate in an alkaline circuit improved both selectivity and barite recovery, which was increased to a range of 70 to 75 percent.

Read More

Operating and Troubleshooting a Grinding Circuit - 911

When in fact they hadn’t finished climbing yet. The results could be an overloaded grinding circuit, and a very poor grind. When a circuit becomes overloaded it is because the amount of ore that is going out of the overflow is less than the total volume of the ore coming into the circuit. What is known as a CIRCULATING LOAD builds up.

Read More

General Process Introduction Of Barite Beneficiation

2023.9.5 The general process of barite beneficiation includes crushing, grinding, screening, gravity separation, flotation and drying.According to the actual ore type, sometimes washing and magnetic separation processes are also included.JXSC our barite beneficiation process and equipment, impurities can be removed and the purity and

Read More

(PDF) Optimization and performance of grinding circuits: the

2020.1.16 Currently, the grinding circuits are inefficient in achieving the aspired product fineness of x P 80 = 125 μm even at low to normal throughputs (450-600 t/h).

Read More

Simple Grinding Circuits Flowsheets - 911 Metallurgist

Open Circuit Primary Ball Mill + Closed Circuit Secondary Ball Mill with Cyclone. These circuits have been getting more and more complex. This is because the ore and the required grind has been getting more and more complicated. The ore in the first one was the softest and the grinding wasn’t critical.

Read More

The basics of grinding circuit optimisation - CEEC (Coalition for

2018.8.31 The basics of grinding circuit optimisation. A Giblett and B Putland. 14 th AusIMM Mill Operators’ Conference, 29-31 August 2018, Brisbane, Australia. ABSTRACT. This paper provides a simple guiding framework for grinding circuit optimisation, focussing on common.

Read More

Kinetics of dry grinding of industrial minerals: calcite and barite

2002.11.1 This paper presents the kinetics study of dry ball milling of calcite and barite minerals. The experimental mill used was a laboratory size of 209 mm diameter, 175 mm length, providing a total mill volume of 6001 cm 3, with a total mass of 5.6 kg of steel balls of 46, 26 and 12.8 mm diameter, so as to occupy 20% of the mill volume and with a

Read More

Kinetics of dry grinding of industrial minerals: Calcite and barite

2002.11.1 This paper presents the kinetics study of dry ball milling of calcite and barite minerals. The experimental mill used was a laboratory size of 209 mm diameter, 175 mm length, providing a total ...

Read More

Comparison of Particle Shapes of Conventionally Ground Barite

Ball and rod mills are commonly used as conventional grinding mills to produce a controlled grind size for the flotation circuit in the beneficiation of industrial minerals. Dynamic Image Analysis (DIA) offers reproducible results of a huge number of particles for some industrial minerals namely, barite [1], calcite [2] and talc [3] particles, whose shapes are crucial for

Read More

One of the Biggest Finished Barite Suppliers ADOUSA

CS Mining - Barite Group, is formed of 9 companies located in Turkey, Morocco, Canada and Unites States of America, which are respectively ADO Mining, Baser Mining, ... 1.100.000 TPA Grinding Packaging. 02

Read More

The effects on the grinding parameters of chemical

2022.1.1 Recently, kinetic model has been mostly used to the design of grinding circuits.In this study, the relationship between the Bond's grindability (Gbg) and breakage parameters (Si, aT, γ and β ...

Read More

grinding circuit - 英中 – Linguee词典

大量翻译例句关于"grinding circuit" – 英中词典以及8百万条中文译文例句搜索。

Read More

Redalyc.Circulating load calculation in grinding circuits

complexity of the circuit, with low com - putational demand and high convergence speed of the result. 2. MATERIAL AND METHOD Figure 1 Grinding circuit closed by a hydrocyclone. 2.1. Algorithm’s general formulation Analyses of many existing mineral proces- sing circuits were carried out, observing the behavior of the mass flows through

Read More

Barite Ore Beneficiation - JXSC Machinery - Mineral Processing

The composition of barite ore is complex, and there are strict requirements on the fineness of the product in application. The common barite beneficiation process are hand selection, gravity separation, flotation and magnetic separation. JXSC supports customized complete set of barite processing plant and equipment according to the specific types of barite

Read More

Increasing Grinding Circuit Robustness with Advanced Process

grinding circuits. Often the attractiveness is further increased by rather low investment requirements and fast payback periods. This paper discusses the structures and options for grinding circuit instrumentation and advanced process control. Three case studies at standard AG/SAG and ball mill grinding circuits with actual

Read More

barite gravity separation circuits

Method of processing barite Beneficiation process CommonChallenges Relative to the Use of . Gravity Separation Concentration Methods Could you please recommend me some paper about separation of galena from barite with using flotation and gravity method Bob Mathias In your case a lot more details are required before looking at the suitability of

Read More

Barite grinding mill selection and Raymond mill

2018.12.6 Among them, 200 mesh barite powder is the more commonly used fineness standard, and in the equipment selection, the HD series raymond mill produced by Guilin Hengda Mining Machinery Co., ltd is ...

Read More

AMIT 135: Lesson 6 Grinding Circuit – Mining Mill

Design features of grinding equipment (SAG, BALL and ROD MILLS) Explain typical flowsheets of grinding circuits involving single or combination of equipment; Reading Lecture. Size reduction by

Read More

Flotation recovery of barite from high-density waste drilling fluid ...

2024.3.14 2.1. Minerals and reagents. High-density waste polysulfide drilling fluid was obtained from the centrifuge discharge port of a shale gas well in southwest oil and gas field, the density of drilling fluid is 2.150 g/cm 3, the water content is 10.00%, and the barite content is 79.00%.. Dilute hydrochloric acid as pH adjuster, analytical-grade sodium

Read More

Crushing Grinding Circuit Design - Comminution

2018.4.17 (Fig. 1) From this circuit, complexity increases to multi-stage crushing circuits preparing feed for multi-stage grinding circuits. Fig. 2 showing a three stage rod mill ball mill arrangement is an example

Read More

Reinforcement Learning for Grinding Circuit Control in Mineral ...

Grinding, i.e. reducing the particle size of mined ore, is often the bottleneck of the mining concentrating process. Thus, even small improvements may lead to large increases in profit. The goal of the grinding circuit is two-sided; to maximize the throughput of ore, and minimize the resulting particle size of the ground ore within some acceptable range. In

Read More

Baryte Processing Equipment, Process Flow, Cases - JXSC Machine

2019.8.26 Barite magnetic separation. A wet magnetic separator is usually used to select some iron-bearing materials such as siderite, which are used as barite feedstock for baryte based pharmaceuticals with very low iron content. Barite flotation process. 1. Grinding fineness: Flotation of barite generally requires grinding fineness—200 is 85 ~

Read More

Operating a Grinding Circuit -How to Operate - 911 Metallurgist

2015.7.29 What I would like to do now is expand upon the grinding theory involved. Bring all of the earlier information together and show you how it relates to the operation of a mill and make you capable of Operating a Grinding Circuit correctly. Then I will explain the differences between Rod mills, Ball mills, SAG and autogenous mills and how to operate

Read More

Grinding circuit modeling and simulation of particle size control

2010.9.15 The result of the clustering can be presented using a dendrogram graph, where the groups are linked according to the distances. Fig. 2 a shows a dendrogram of the Siilinjärvi grinding section data; the number of data observations in each cluster is seen in Fig. 2 b. The number of clusters was selected to be nine, since denser cluster resolution

Read More

Mineral Crushing and Grinding Circuits Semantic Scholar

Mathematical modelling and automatic control of mineral crushing and grinding circuits have been studied at the Queensland Julius Kruttschnitt Mineral Research Centre for several years. While much is still to be done, it is considered that knowledge of the subject has reached the point at which a useful monograph may be published. The emphasis in

Read More

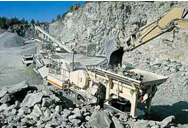

How it Works: Crushers, Grinding Mills and Pulverizers

2017.6.2 Table Source: Wikipedia (Crushers) Cone crushers use a spinning cone that gyrates in the bowl in an eccentric motion to crush the rock between the cone surface, referred to as the mantle, and the crusher bowl liner.Gyratory crushers are very similar to cone crushers, but have a steeper cone slope and a concave bowl surface. As the gap

Read More

Grind Circuit Training Grind Circuit

THE GRIND DON’T STOP. BOOK BASKETBALL TRAINING. March- April TRAINING SCHEDULE. UPCOMING EVENTS. 2024 EASTER CLINIC. REGISTER HERE. BASKETBALL TRAINING . BALL HANDILNG, SHOOTING, DEFENSE AND MORE! Video Player is loading. Play Video. Play Skip backward 10 seconds Skip forward 10 seconds.

Read More